Radiography Testing

This type of inspection is widely used for deep defect in welded products, forging and casting.

Principle

X-rays of gamma rays can penetrate through solid material; during transmission through the material some of the ray is absorbed. Absorption increase with density. If a photographic film is placed on the other side of material, the defect can be found out.

Fig 1

X rays

X-rays are produced in an X-ray tube, where a cathode filament provides electron, which proceeds towards the target (anode), strike and are suddenly, stopped. A part of their kinetic energy is converted to energy of radiation or X-rays.

The specimen is placed in between these X-rays and photographic film. The defects like blowholes, crack, and porosity etc possess lesser density than sound material of the casting they transmit the x-rays better than the sound metal does. Therefore the film appears to be darker where defects are in line of the X-rays beam. Fig 14.12(a), (b) and (c) show the radiograph of sound casting and casting containing blow holes and porosity respectively

Fig 2 a,b,c

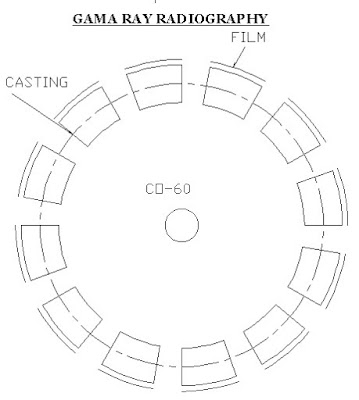

Gamma Radiography

Gamma rays are produced by the dis-integration of radioactive material such as radium, Co-60 etc. This is similar to x-ray technique. Gamma ray penetrates more effectively into the metal, since gamma rays have shorter wavelength than x-rays. So it has greater penetrating power and produce sharper images. The specimen is placed of definitive distance form the source with a photographic film behind the object.

Comparison between X-rays and gamma rays radiography

Unlike x-rays, gamma rays from it source are emitted in all direction. Therefore the no of separate specimen can be tested at a time using gamma radiation

No electricity is needed for gamma testing

X-ray method is much more rapid than gamma ray method because it requires only a few sec/min instead of hours.

Gamma ray equipment is being small possesses better portability and convenience of use [off radium] for second feed inspection.

Gamma rays give radiation hazards

Limitation of Radiography testing:

It can indicate the shape of a defect at right angle to the direction of testing but single exposure cannot indicate the depth at which it lies.

COMMENTS