14.0 MULTI DAY LIGHT MOULDS

14.1 Introduction:

When a basic mould (consists of two parts) is opened, there is only one space or "daylight" between the two mould halves. This is called a single daylight moulds (Fig.14-1). In a stripper plate mould, which consists of a fixed plate, a moving mould plate and a stripper plate, there are two day lights when opened. This is called double daylight stripper plate mould (Fig. 14-2)

Another type of mould also consists of three main plates - a feed plate, a floating cavity plate, and a moving mould plate has two day light and is termed as double day light under feed mould or three plate mould. This design permits a particular feed technique known as underfeeding.

A combination of stripper plate and underfeeding results in a triple daylight mould (Fig. 14-3)

14.2 Underfeed Moulds:

An underfeed mould is one in which the feed system is arranged to feed into the under side of the component. To underfeed, the mould is basically a two-plate mould with as additional plate mounted on the front. This plate, termed as feed plate, incorporates the runner, which can be directed to any point on the cavity plate.

The main uses of the underfeed type of moulds are;

- Mouldings produced on multi-impression mould can be center feed.

- Off center feeding can be achieved for both single and multi impression moulds.

- Multi point feeding can be accomplished on both single and multi impression moulds.

14.2.1 Basic Underfeed Moulds:

The mould consists of three basic parts-The moving half, the floating cavity plate and the feed plate. The moving half consists of the moving mould plate assembly, support blocks, back plate, ejector assembly and the ejection system. The floating cavity plate is located on guide pillars fitted in the feed plate. Guide bushes are fitted Into the moving mould plate and the floating cavity plate. The movement of the floating cavity plate is controlled by stop bolts. Sufficient space between the feed plate and the floating cavity plate is maintained for easy removal of the feed system. The desired operating sequence is for the first daylight to occur between the floating cavity plate and the feed plate. This ensures that the sprue is pulled from the sprue bush immediately after the mould is opened. To achieve the sequence, springs are provided between feed plate and the floating cavity plate. Extra length bolts are also included to pull the plate the remaining distance if the floating cavity plate stops before completing the required movement.

Since a major part of the feed system is accommodated in the feed plate, the runner should be of a trapezoidal form for easy extraction. If a round runner is used, there are chances of it remaining in floating cavity plate preventing the falling of the feed system.

14.2.2 Operation Cycle

The impressions are filled via feed system and after a suitable dwell period, the machine platen start opening. An immediate force exerted by the compression springs causes the floating cavity to move away with the moving half. The sprue is pulled from the sprue bush by the sprue puller. Movement of the floating cavity plate is arrested by the stop bolts at a pre- determined distance. The moving half continues to move back and the Mouldings are withdrawn from the cavities. The pin gate breaks. The sprue puller is pulled through the floating cavity plate and the feed system is released to fall free. The moving half continue to move back until the Mouldings are ejected.

14.2.3 Types of feed:

The shape of the component affects the design of the floating cavity plate, which in turn determines the form of feed system. The depth of steel situated below the cavity impression should be sufficient to withstand the applied injection force without deflection. A graph of depth of steel required below the cavity impression slotted against the cavity diameter is given in Figure .

Secondary Sprue Gate:

This sprue gate connects the runner to the impression instead of the nozzle exit to the impression. The sprue gates must be degated in an extra operation.

Reverse Tapered Secondary Sprue:

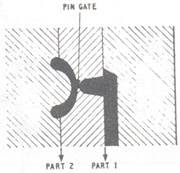

This design allows a pin gate to be used. The secondary sprue gate terminates a short distance from the impression. A standard type of pin gate can be used. In this method, the feed system is not free to fall when the mould is opened because the secondary sprues are retained within the floating cavity plate. The feed system must be removed by hand. This can be avoided by the following method

14.3 Underfeed Runner System- Design1:

This design has a runner which is under cut at either end in the feed plate and it delayed the acting sprue puller as in the figure below. The mould opens at P1 and because the runner is retained in the feed plate by the undercuts, the pin gate breaks. The sprue is not pulled at the stage because of the float permitted by the puller. The moving mould half and the floating cavity plate move back together leaving the feed system in the feed plate. When the runner's floating distance is exceeded, the sprue is pulled, and

because of the undercuts, the runner is distorted as it is pulled from the feed plate. The floating cavity plate is arrested and the Mouldings are withdrawn from the cavities. The feed system is released as the puller is pulled through the floating cavity plate. Continued movements of moving half causes the Mouldings to be ejected. The following points to be considered in this design. .

- The floating period must be sufficient to permit the reverse tapered sprue to clear the cavity plate before the puller pulls the sprue.

- Considerable runner deflection is necessary to ensure that the secondary sprues are not pulled back into their holes when the puller is activated.

- The diameter of the puller must exceed the width of the runner to ensure that the puller is pushed back to it's position when the mould is closed.

14.4 Undercut Runner System -Design 2:

For this design, the float period is achieved by secondary puller (Fig. below). When the mould is opened, the sprue is pulled immediately by the sprue puller. The entire feed

system moves back with the cavity plate along with secondary pullers. When the floating distance of secondary puller is exceeded the feed system is arrested and the secondary sprues are withdrawn. Further movement causes the distortion of the runner and the feed system is released. Finally the Mouldings are pulled from their cavities and are ejected. The points to be considered in this design are

- The secondary pullers must be keyed in order to prevent their relations.

- A front plate is necessary to support the heads of secondary pullers.

- There is a tendency for the feed system to be retained by the secondary pullers when the mould is opened. A pneumatically operated wiper can be used to eject the feed system.

14.5 Runner Stripper Plate Design:

A positive pulling of the secondary sprue from the floating cavity plate and a positive ejection of the feed system is achieved in this design. A fixed secondary puller is fitted directly below the secondary sprue. A runner stripper plate is used to release the feed system from secondary pullers.

As the mould opens, the secondary pullers retain the feed system, causing the gate to be broken and the secondary sprue to be withdrawn. The feed system is stripped from the pullers by the stripper plate. When the delay distance of shoulder bolt is exceeded the movement of stripper plate and cavity plate is arrested. Now the final opening occurs and the Mouldings are drawn from the cavities and are ejected.

Design features

- The runner stripper plate must be of the same size as the other mould plates and is mounted on the main guide pillars.

- A bush can be used in the stripper plate for the sprue bush. This permits the replacement of bush when wear occurs. In order to avoid wear, the sprue bush can be tapered at the front end corresponding angle should be provided with stripper plate hole.

- The sprue must be kept as short as possible by sinking the head of the sprue bush well into the feed plate. An air jet arrangement is used to blow the feed system clear.

- Extra length bolts should be used to pull the floating cavity plate positively to the correct position

There are two alternative designs

- Under feed / runner stripper plate design with an extended nozzle.

- Under feed / runner stripper plate design with a heated sprue bush

In type 1, a heated extended nozzle protrudes into the front face to the mould and touches the front face of the floating cavity plate. The nose of the nozzle fits into the stripper plate. In type 2, a heated sprue bush is used as a part of the mould structure.

Underfeed/runner stripper plate design Underfeed/runner stripper plate design

Incorporating a heated sprue bush incorporating an heated sprue bush

14.6 Stripper Daylight Mould:

The four basic plates in this assembly are the feed plates, the floating cavity plate, the stripper plate and the moving mould plate. A combination of stripper plate design and under feed design results is a triple daylight moulds. Therefore the location and number of guide pillars must be considered. The guide pillars can be mounted in the feed plate for supporting the cavity plate and aligning the cavity and core. The stripper plate is supported on tie-rods, which connects the stripper plate to the ejector assembly. Tie-rod bushes are provided in the core plate. In an alternative design, the guide pillars are mounted in the core plate for supporting stripper plate only. And secondary guide pillars are used.

This design has certain disadvantages.

- A longer mould area is necessary for the extra guide pillars.

- The temperature control system is more complex because of the number of large diameter holes.

- The guide pillars tends to box in the moulding

With the limited mould height, the direct actuation of the stripper plate is possible. As the mould opens, the sprue is pulled immediately by the sprue puller. The feed system moves back with the cavity plate. When the floating distance of the sprue puller is exceeded, the feed system is arrested and the gates break and the secondary sprue are withdrawn. Continued movement causes the moulding to be drawn from the cavity and is ejected.

Go to Moulding page

Go to Home Page

COMMENTS