LASER BEAM MACHINING (LSM)

A Laser (Light Amplication by Stimulated Emission of Radiation) is a device, which produces a beam of light. Laser light can be very powerful source of power. In LBM, exceedingly high electromagnetic energy densities (of the order of 105 kW/mm2) are focused on the surface of the workpiece (in air or vacuum) to remove metal by melting and evaporation.

There are many types of lasers used for different purposes, e.g. solid state, gas, liquid and semi-conductor. For machining and welding, high power lasers are required and, in general, only the solid state lasers can provide the required power levels.

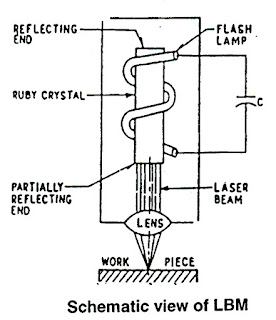

The most commonly used solid-state laser is the ruby laser (crystalline aluminium oxide or sapphire). These lasers are fabricated into rods about 150 mm long and their ends are finished to close optical tolerances. Figure shows a schematic view of LBM.

The ruby crystal is doped with a small amount of chromium oxide. The laser is "pumped" by a flash of high intensity light (A xenon-filled flash lamp). The xenon lamp is fired by discharging a large capacitor through it (electric power of 250 to 1000 watts may be needed for this). The intense radiation from the-lamp excites fluorescent impurity atoms (chromium atoms) to a higher energy level. When the atoms fall back to the original energy level through a series of energy levels, an intense beam of visible light is emitted. When this light is reflected back from the coated rod ends, more atoms are excited and stimulated to return to their ground level. This chain reaction results in a stimulating avalanche of light, some of which is transmitted through the reflecting coatings (80% reflective). This light is highly coherent in time and space, that is, it has a very narrow frequency band, is highly in phase, and is quite parallel. When this light is focused with ordinary lenses at spot on the workpiece, high energy density is obtained which will melt and vaporize the metal. It is clear that LBM is a pulsed operation. After discharge, the capacitor must be recharged. Power supply is : Potential = 4.5 kV, current = 2A. The ruby laser works with maximum efficiency when kept at a very low temperature. For this, liquid nitrogen at - 196 deg. C is employed. On the other hand, the light flash works best when warm. For this, hot air is circulated over it. The vacuum chamber between the ruby crystal and the flash lamp acts as an insulator and enables the two temperatures (discussed above) to be maintained. The flash lamp operates from 1 flash every 3 min to 12 flashes per minute. The laser beam energy is applied to the workpiece in less than 0.002 s.

Product Applications: LBM is again a "micromachining" method which can be used for drilling, scribing, cutting and shaping. Holes as small as 0.005 mm in diameter have been produced. It has got the following drilling applications: -holes in rubber baby bottle nipples; nozzles, in surgical and hypodermic needles; flow holes in oil or gas orifices etc. LBM is finding increasing use in industrial and non-industrial fields.

As compared to EBM, LBM has higher energy density levels and it does not need vacuum for its operation.

COMMENTS