JIG BORING

Introduction:-

The jig boring machine is the most accurate of all machine tools. This was first developed in the year 1910 in Switzerland and used as a locating machine. The real jig borer was first built in the year 1917 by Pratt and Whitney

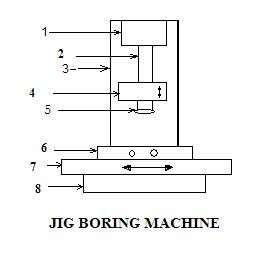

1. Spindle head 2. Quill 3. Column 4. Spindle housing 5.7. Spindle 6. Table 8. Bed

Jig boring machines are now used for production of jigs, fixtures, tools and other precision parts which require high degree of accuracy. They are characterized- by provisions of highest accuracy through rigidity, low thermal expansion and precise means of measuring distance for accurately locating and spacing holes. The machining accuracy is very high, within a range of 0.0025 mm. A jig boring machine resembles in, appearance to a vertical milling machine, but so far its operation and accuracy are concerned there cannot be any comparison between the two. The -spindle and other parts of the machine are extremely rigid to, resist deflection -and the vibration is minimum. The spindle runs in preloaded antifriction bearings,. The spindle housings are made in invar having a very low coefficient of linear expansion. The jig boring machine requires to be operated in temperature controlled rooms where temperature can be maintained constant. This is essential to prevent inaccuracy in the machine and in the work being manufactured due to thermal expansion of the metal.

Parts of a Jig borer:-

A jig borer has the essential element of a vertical spindle milling machine. For the sake of attaining high accuracy, it is generally built lower to the floor and is much more rigid and of accurateconstruction. On the base of it, a saddle is supported which moves in and out from the operator to the column. To supplement the saddle movement, a table isprovided on it, which can move to right or left. It has a massive columnwhich supports the spindle housingand is capable of moving up and down the column ways. Thus the third position adjustment is achieved.

The spindle moves inside a quilt and is supported by the housing or spindle head. In order to add to the rigidity of the machine tool, the quill is made capable of moving up and down inside the housing thus giving a telescope mechanism. In order to eliminate the lost motion for purpose of high accuracy and precision, the spindle quill and housing are manufactured under extremely careful and exacting conditions and to minimise the errors due to expansion, the housing is made of invar cast iron The spindle is hardened, ground, stabilised and tapped and pre-loaded ball bearing are used., The drying mechanism-provided is capable of giving speeds ranging from about 30 to 1500 RPM. So that best cutting speed is available for each size of hole.

For aligning the job and centering it, a dial indicator fitted on the spindle is used. Usually the operator located the points etc. from either a finished edge or from a suitable hole while setting up for boring operation. The dial indicator is used to pick up the surface and then with reference to it, the spindle can be set.

Types of jig boring machine

There are mainly two types of Jig boring machine :

1. Vertical milling machine type

2. Planer type

1.Vertical milling machine type : It resembles in construction to a vertical milling machine. The spindle rotates on a vertical column and the horizontal table rests on the bed in front of the column. The positioning of the work mounted on the table may be obtained by compound movements of the table, perpendicular and parallel to the column face.

There are mainly two types of Jig boring machine :

1. Vertical milling machine type

2. Planer type

1.Vertical milling machine type : It resembles in construction to a vertical milling machine. The spindle rotates on a vertical column and the horizontal table rests on the bed in front of the column. The positioning of the work mounted on the table may be obtained by compound movements of the table, perpendicular and parallel to the column face.

2.Planer type : It consists of two vertical columns at the two sides of the table and is mounted on the base. The table has reciprocating movement for adjustment of the work. The spindle is mounted on the crossrail bridging the two vertical columns. In a planer type Jig borer, two co-ordinate movements for hole location are provided by the longitudinal movement of the table and the cross movement of the spindle along the crossrail.

COMMENTS